Common descriptions of the main waterproofing materials using in construction process and appropriate cases of using each of them.

Waterproofing materials are construction materials having water resistance and certain performance requirements for strength, heat resistance, deformability, biological stability.

List of main waterproofing materials:

reinforced plates,

reinforced plates,- asphalt reinforced mats,

- bitumen and bitumen membranes,

- brizol,

- tar-bitumen materials,

- izol,

- metallic izol,

- hydro izol,

- unreinforced slabs,

- glassine,

- prepared roofing paper.

Reinforced plates

They are produced by hot pressing or hot mastic asphalt mixture applying reinforcement by fiberglass or metal gauze. They are most commonly used for walls.

Asphalt reinforced mats

They are obtained by coating both sides with waterproofing mastic previously impregnated by fiberglass. They are used for pasting waterproofing for roofs (of a flat type) and sealing joints.

Bitumen

It is commonly known as an organic binder and a product of oil refining.

- solid,

- semi-solid,

- liquid oil.

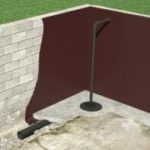

Bitumen is divided into five grades (with the increasing in the melting point). On the construction and waterproofing process bitumen of the fourth and fifth grades used more often as having the most heat resistance. An important feature of bitumen is its chemical resistance, so it is used for chemical protection of steel pipes and reinforced concrete structures. It is widely used in the form of membranes in waterproofing processes for walls, roofs, foundations, for terraces as well.

Brizol

Brizol is made by laminating the mass obtained by mixing petroleum asphalt, crushed rubber from used tires, asbestos fiber and plasticizer. Brizol is resistant to hydrochloric acid and sulfuric acid. Brizol is commonly used to protect metal structures against corrosion. Brizol is glued to the surface with mastic.

Tar-bitumen materials

They are prodused in the form of cardboard impregnated with tar (which prevents cardboard’s rotting), it is coated with bitumen and grit on both sides. Its rotting resistance is due to the high toxicity of tar in phenol (carbolic acid).

Izol

Popular roof waterproofing material which is made by rolling bituminous composition obtained by thermo-mechanical processing of rubber, oil bitumen, mineral filler, antiseptic and plasticizer. Isol is 2 times more durable than the prepared roofing paper. Isol is quite elastomeric, it slightly absorbs moisture. It is also used for waterproofing foundations and as corrosion protection of pipelines. Izol is glued with mastic. It is produced in rolls of a width of about 1 foot.

Metallic izol

The waterproofing material made of aluminum foil and covered with mastic asphalt on both sides. Metallic izol has high tensile strength and durability. It is available in two grades which differ in the thickness of aluminum foil. Metallic izol widely used for buildings with underground structures.

The waterproofing material made of aluminum foil and covered with mastic asphalt on both sides. Metallic izol has high tensile strength and durability. It is available in two grades which differ in the thickness of aluminum foil. Metallic izol widely used for buildings with underground structures.

Hydro izol

Hydro izol is a roll waterproofing material obtained by impregnating asbestos board with oil bitumen. It is used as a waterproofing layer in underground structures and as protective anti-corrosion coating.

Unreinforced slabs

They are manufactured by compressing hot mix asphalt mastic or without reinforcement. These plates are used for waterproofing and filling expansion joints.

Glassine

It is rolled material received by impregnation of a roofing cardboard with molten bitumen oil with a softening point of not lower than 105 ° F. Glassine paper is used as a lining material for roofing waterproofing.

Prepared roofing paper

Prepared roofing paper is manufactured by impregnating roofing paper with fusible bitumen, on one or both sides it is covered with oil bitumen with a filler and grit. Roofing paper is produced from waste paper, rags and wood pulp. Weathering and attractive looking of this material are achieved by using a coarse-grained color spreading. To prevent sticking of the material while being in rolls a layer of roofing felt roofing grained sprinkling is covered on its both sides (or just on the underlay side). The main drawback of prepared roofing paper is that it is prone to rotting. The new tendency nowadays is producing antiseptizated prepared roofing paper.

Prepared roofing paper is manufactured by impregnating roofing paper with fusible bitumen, on one or both sides it is covered with oil bitumen with a filler and grit. Roofing paper is produced from waste paper, rags and wood pulp. Weathering and attractive looking of this material are achieved by using a coarse-grained color spreading. To prevent sticking of the material while being in rolls a layer of roofing felt roofing grained sprinkling is covered on its both sides (or just on the underlay side). The main drawback of prepared roofing paper is that it is prone to rotting. The new tendency nowadays is producing antiseptizated prepared roofing paper.

Toll

Toll is rolled material manufactured by impregnated roofing paper and coated with tars grained sand or mineral crumbs. Tol with sand grit is more often used for waterproofing of foundations and other parts of buildings, as well as for roofs of temporary structures; coarse-grained tall is used for the upper layer of flat roofs.

Foil

Foil is rolled two-layer material consisting of a thin smooth or corrugated aluminum foil coated on its underside with the bitumen-rubber protective coating. This material is used for sealing joints and for the device of roofs. The exterior surface may be painted, foil weatherproof paints in different colors. It is durable, requires no maintenance during the operation period.

We hope this article has provided you a quite good view of waterproofing materials on today’s market.

You May Also Like

The important information about the basic types of roofing materials.