Peculiarities of PVC waterproofing membrane. Its water resistant, vapor permeable and other useful qualities. Main points of its installation technology

PVC waterproofing membrane is a modern roofing material, which is made of high quality flexible (plasticized) polyvinylchloride.

Depending on the application area there are reinforced and unreinforced membranes. Reinforced waterproofing membrane has a reinforcing base in the form of polyester mesh or glass fiber and it is used for waterproofing of roofs. Reinforced membranes have increased durability. Unreinforced membranes are more flexible, have high tear resistance and are used for waterproofing of underground structures, tunnels, swimming pools.

Manufacturers of PVC membranes offer diverse width and length of the material. The width of the material ranges from 3 to 7 ft. The rolls can be between 60 and 75 ft in length. The thickness of the PVC membrane is 1.2 mm. Such diversity in the selection of PVC membranes allows laying the roof of any complexity with a minimum of seams and labor costs.

Specifications of PVC membrane

PVC membrane is used mainly for waterproofing of buildings and roofs. Since this material is quite easy to install, strong enough (is of great tensile strength), has long service life, all this puts the PVC membrane to a higher level comparing to bituminous roofing materials, especially considering that such materials need constant maintenance and repair.

Due to its structure, the PVC membrane is very strong and simultaneously flexible material which is resistant to precipitation, ultra-violet radiation, capable to withstand heavy surface and tensile loads.

Due to its structure, the PVC membrane is very strong and simultaneously flexible material which is resistant to precipitation, ultra-violet radiation, capable to withstand heavy surface and tensile loads.

Among the features of PVC waterproofing membrane its vapor permeability should be highlighted. Due to this characteristic the material can let moisture out of roof space of the building. Thus the building insulation (if applied) does not become wet and does not condense moisture. Also, if some parts of the membrane are damaged, vapor permeability will also contribute to the removal of moisture from the building. In this case there is no need to carry out immediate repair of the roof.

Main advantages of PVC waterproofing materials

PVC membranes are one of the latest high-tech solutions for waterproofing of roofs, foundations and so on. Unlike bituminous materials PVC films have higher:

strength;

strength;- elasticity and tightness;

- strength of the welds (at the junction of sheets);

- atmosphere and chemical resistance;

- vapor permeability at 100% water resistance;

- resistance to wind loads;

- frost-proof;

- resistant to changes in temperature;

- precision in the execution of complex elements;

- resistance to the movements of structural elements of buildings;

- resistance to oxidation and UV rays;

- high durability;

- fast to mount;

- fire resistant;

- diversity of colors.

Membrane roofing is good for covering flat roofs. Thanks to the additional usable space on such roofs it is possible to arrange a place for recreation and entertainment, they are covered with a carpet of vegetation. Here the membrane covering of the roof is simply irreplaceable. PVC waterproofing membrane can serve for almost fifty years without losing its reliability and positive characteristics.

Manufacturers offer a variety of coloring for application of PVC membranes on flat roofs of new buildings (for example, for sports on a well-fenced roof). Experts specify that the PVC membrane does not require additional maintenance during operation.

Installation technology of PVC waterproofing

After preparation of the basis the sheet of drainage geotextiles is laid. Then the roof is further insulated with foam polystyrene or basalt wool. Then you can start the installation of the membrane coating.

After preparation of the basis the sheet of drainage geotextiles is laid. Then the roof is further insulated with foam polystyrene or basalt wool. Then you can start the installation of the membrane coating.

For waterproofing of structures with PVC membrane special hot air welding machine and building dryers are used. Welding is carried out by hot air using automatic equipment which optimizes the temperature, speed and pressing force. Welding with the manual dryer is applied at the junctions and at the places where use of machines is not possible. This technology of bonding the two waterproofing sheets ensures reliability of the seam and fully sealed surface. The average service life of PVC membrane is 30 years, depending on the manufacturer and the quality of installation. Mounting of the PVC waterproofing is carried out in a single layer, which has a positive effect on the cost of the work.

Another advantage of the PVC membrane is that the installation can be performed in wet and frosty weather.

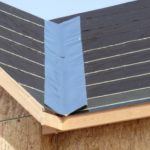

For contiguity of the PVC membrane, a special laminated plate is used. Lamination is carried out by spraying of the PVC on the metal surface. When welding the membrane to the laminated sheet we obtain an unbreakable monolith.

Alternatively, the membrane can be attached with adhesive compositions, or by using the ballast layer of gravel.

PVC waterproofing membrane: benefits and ways of application

When you stated that PVC roofing was fireproof, I found that really interesting. These are the kinds of materials that I can really get behind since my area is known for some pretty gnarly heat every now and then. I’ll protect my home by having a PVC roofing expert get me some right away.

Good Evening

We are looking for PVC Membrane 2MM for Roof Waterproofing – 10000 SQM.

So please share your TDS and price.

Pingback: Waterproofing 101 - Prevent and Repair Roof Leakage in Singapore - Solar AI Technologies