A cinder block foundation is probably the cheapest kind of belt-type bases. The price of cinder block is minimal, and the technology of construction can be mastered by any builder, even a beginner.

A cinder block foundation is probably the cheapest kind of belt-type bases. The price of cinder block is minimal, and the technology of construction can be mastered by any builder, even a beginner.

A method of production of cinder blocks

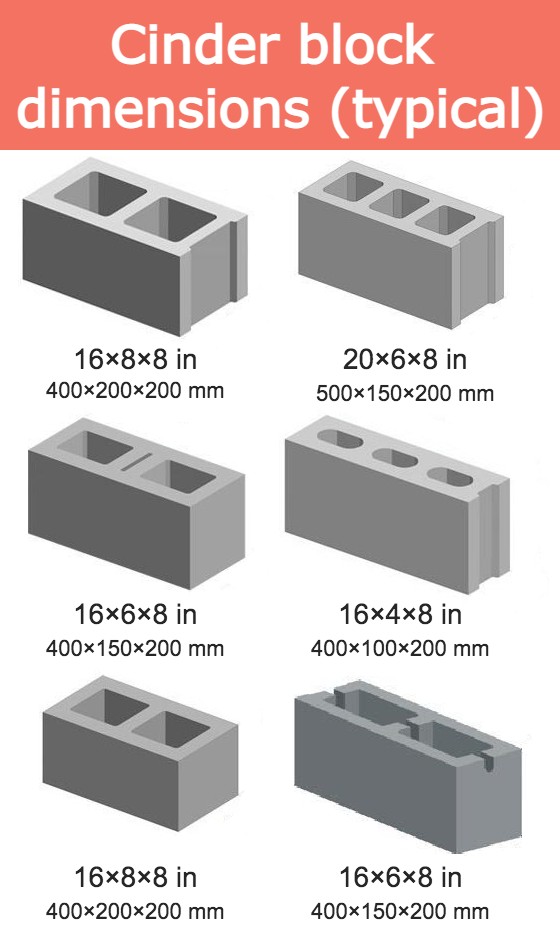

Typical cinder blocks are usually made of a mix consisting of a dry part (that consists of sand, cement, slag dump or brick battle) and water. Building a cinder block foundation a consumer of these products solves two problems at once: it helps to dispose of secondary raw materials (non-toxic waste of any kinds of production) and reduces the cost of building materials. Foundation block dimensions (length, width, height) are usually standard – about 15*7*8 inches.

Advantages and disadvantages of a cinder block foundation

- Cheapness – the building material consists of waste by half or even more;

- Durability – this type of a foundation can withstand up to 100 tons;

- Frost-resistance – hollow block keeps the body even better than products made of foam;

- Size advantage – due to its relatively small weight and size a cinder block, being however large enough, makes the construction process faster than similar work based on laying bricks or installation of concrete products.

Disadvantages:

- Insufficient hydrophobicity – such unit absorbs moisture from soil and atmosphere; this may affect the durability of the product in quite a negative way;

- The high thermal conductivity of monolithic products – the entire unit, with its voids, can not prevent the unwanted heat transfer between the heated room and the street;

- Insufficient strength in the transverse direction – sometimes it can not hold a transverse load in a proper way.

Building a cinder block foundation

Attention! The walls of the basement should be insulated without fail (even if the building will be erected on dry ground). It is necessary not only to protect the vertical plane of cinder blocks, but also to lay a horizontal layer between the underground and above-ground parts of the building. This helps to prevent the extra moisture of house walls because of capillary moisture.

Laying the base is only possible on relatively dry soils with low levels of underground waters and the shallow depth of soil freezing. In addition, a cinder block foundation can not be built on clay (or similar) grounds. The reason for this is lack of lateral stability.

Laying the base is only possible on relatively dry soils with low levels of underground waters and the shallow depth of soil freezing. In addition, a cinder block foundation can not be built on clay (or similar) grounds. The reason for this is lack of lateral stability.

So, if your site is in a zone of deep groundwater or soils containing no unnecessarily moving beds, the construction is following.

First, you should dug trenches for tape bases or settle pits for columnar ones. Then, on the bottom of the trenches or the pits pour a layer of sand and gravel. Spread prepared roofing paper for waterproofing of your foundation bottom. On a layer of roofing material a precast concrete block can be installed, or pour a reinforced sole (4*4 inches grill), then concrete it. After the arrangement of the foot on the concrete you should lay the first row of blocks (in case of construction of the tape base) or the first layer of blocks (in case of the construction of the columnar base). A subsequent row/layer is placed from the corners to the center, connecting the upper and lower layers with rather thin (less than 0,5 inch) layer of bonding solution. This operation is repeated until the completion of the needed height. The upper part of your foundation should be made of reinforced concrete, wood or metal. At the end the walls of the basement are usually covered with a layer of mastic, and the finishing step is, for sure, covering styrofoam panels. You can then fill the pit and go to the construction of the wall structure of your house.

Now your cinder block foundation is ready! The proper exploitation will let it serve you well for long decades.

How to build a cinder block foundation