The most common types of waterproofing materials used in construction; their composition, properties and application areas.

Many construction materials are not highly resistant to moisture. Therefore a very important aspect of any construction process is to ensure the protection of materials. Modern market of construction materials is represented by a lot of types of waterproofing that are designed to effectively protect the foundation, roof, walls, and floor structures from the damaging effect of groundwater moisture or precipitation.

Rigid waterproofing

This type comprises waterproof dense concrete, shotcrete, metal waterproofing and sand-cement plaster waterproofing, which is made by hand or by using compressed air.

Stiff sheet waterproofing is made of polymeric or metal sheets. They are fastened to the building envelope by means of anchors, screws, glue, pins or by welding.

Paintable waterproofing

That is a waterproof film which is formed by coating the surface with liquid or plastic materials, such as bitumen, mastic or special paint and varnish, which have corresponding properties, i.e. resistance to moisture.

That is a waterproof film which is formed by coating the surface with liquid or plastic materials, such as bitumen, mastic or special paint and varnish, which have corresponding properties, i.e. resistance to moisture.

Modern waterproofing paints or varnishes have synthetic resins and plastics, which also create excellent protection against moisture.

Lining waterproofing

This type of waterproofing combines two different types: paintable protection and lining waterproofing itself, therefore it has greater efficiency and perfectly protects brick, concrete, metal and other surfaces. Lining waterproofing involves coating the surface with roll or sheet materials. The best type of such coating is roofing felt. It is also possible to use extruded polystyrene, which is glued to the bitumen mastic of hot or cold application method.

Waterproofing with wall putty

This waterproofing consists of different liquid compositions of mastics and mortars (mud) to create continuous seamless waterproofing layers. This is durable waterproofing often used in construction and trimming, as it is resistant to physical, mechanical and chemical influences. It is also sufficiently elastic and does not crack under the influence of weather conditions or differential house settlement.

Plaster waterproofing

Depending on the materials used plaster waterproofing can be divided into three subspecies.

Depending on the materials used plaster waterproofing can be divided into three subspecies.

- Cement plaster, which is applied to the surface in a layer of 5 to 40 mm.

- Asphalt plaster, which is applied in several layers, each one 4 mm thick. The coating represents protection made of hot or cold mastics.

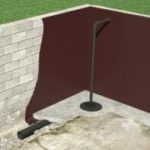

- Molded asphalt waterproofing. It is a solution of hot mastic which is poured into the cavity between the protective wall and the insulated surface.

Penetrating waterproofing

This kind of waterproofing provides good water resistance of concrete structures. It can be applied at the beginning of the building process and in the final stage. Compositions deeply penetrate into the surface with a porous structure.

Also, this waterproofing has the properties of prevention corrosive processes in the reinforcing structures. Also penetrating protection compositions can withstand chemical attack and significantly increase resistance of the surface.

Sprayed waterproofing systems

Sputtering of waterproofing composition is done by a special paint gun or airless spraying pad. Composition which is sprayed on the surface consists of the liquid rubber or a similar acrylic solution applied on any surface.

Manufacturers produce very strong sprayed waterproofing based on polyurethane, acrylic or conventional bitumen compositions.

Injection waterproofing

This type of waterproofing is used for the treatment of cold joints at the junction of walls and the ground in order to eliminate leaks in the walls, to increase the bearing capacity of problem foundation and to prevent capillary leak of soil moisture. Usually foundations and exterior walls are injected.

This type of waterproofing is used for the treatment of cold joints at the junction of walls and the ground in order to eliminate leaks in the walls, to increase the bearing capacity of problem foundation and to prevent capillary leak of soil moisture. Usually foundations and exterior walls are injected.

The composition is prepared on polyurethane, mineral, epoxy or other basis. The solution is injected into the wall with a high pressure. To do this, use special equipment – packers (injectors). When the composition comes out, it forms a waterproof elastomeric membrane barrier between the wall and the ground.

Other types of waterproofing

There are also waterproof polymer films, which are used for roofing. They effectively protect the roofing from moisture. In addition, they pass the steam coming from the covered space excluding occurrence of  condensation.

condensation.

Seam sealing is used for waterproofing of the foundations. It represents paste-like mixture based on acrylic and polyurethane.

For reliable protection of concrete and reinforced concrete from moisture armor waterproofing is applied. It creates a solid layer with high waterproofing properties. It is used mostly for waterproofing of concrete, which is mixed with special additives.

You May Also Like

Types of roofing materials: properties and characteristics.

Types of waterproofing materials and their function