Basic features of aluminum waterproofing membrane. Its diverse functions and application areas. Tips on laying the material.

Aluminum waterproofing membrane is surfaced or self-adhesive roll roofing and waterproofing material, consisting of aluminum foil coated with the layer of bitumen-polymer binder on the underside and reinforced with a glass fabric or polyester. The foil gives the material properties of thermal insulation and improved durability, protecting the bitumen-polymer binder from the destruction caused by ultraviolet radiation.

Application areas of aluminum waterproofing

These are the multi purpose materials, because in addition to waterproofing and vapor barrier they can also serve as energy-saving, vibration isolation and sound-proof material.

These are the multi purpose materials, because in addition to waterproofing and vapor barrier they can also serve as energy-saving, vibration isolation and sound-proof material.

- The roof:

- arrangement of single and double-layer coating of flat and pitched roofs of any complexity;

- arrangement of flat and pitched roofs of corrugated steel sheeting, slate, ceramic, bitumen and other rolled materials.

- Pipelines: waterproofing of hot and cold water pipes’ insulation, and waterproofing of oil and gas pipelines.

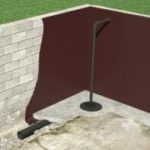

- In construction for waterproofing of foundations, basements, parking lots, floors, swimming pools, drainage systems, underground containers.

- For vibration isolation of ventilation systems, premises and working equipment.

- Airfields, bridges and highways: arrangement of heat reflecting waterproofing coating of runways and highways, waterproofing of bridges and tunnels.

Pros of using aluminum waterproofing membrane

- Reduction of the work costs, ease of installation and high fire safety when applying the self-adhesive foil;

- reflection of thermal radiation;

- mounting on different bases (concrete, wood, metal, plastic etc.);

- cleanness of the roof membrane and possibility of painting it in any color;

- biological stability, durability and reliability.

Aluminum foil reflects the heat better than other materials, protects from damage and provides high durability of the waterproofing layer, greatly increasing the life of the material. Aluminium waterproofing membrane can be used in all climatic zones. It can freely bend at temperatures down to 5°F and has thermal resistance up to 248°F. Thick foil provides high strength of the material.

Aluminum foil reflects the heat better than other materials, protects from damage and provides high durability of the waterproofing layer, greatly increasing the life of the material. Aluminium waterproofing membrane can be used in all climatic zones. It can freely bend at temperatures down to 5°F and has thermal resistance up to 248°F. Thick foil provides high strength of the material.

Aluminum membrane is designed for the installation and repair of the roofs, for waterproofing of different surfaces and insulation of the pipelines. It is durable, requires no maintenance during the operation period.

Main properties of this material include:

- powerful thermal insulation, vapor barrier and sound insulation properties;

- ease of installation (easy to cut with a knife, is mounted with a furniture stapler, small nails of can be glued with a tape);

- does not rot of corrode;

- environmentally friendly.

Application of aluminum waterproofing membrane

Surfaced aluminum foil is glued to the prepared substrate by reflow of the coating layer on the bottom side by overlapping welding of the loosely lying material. The welding is performed by gas or other burners.

Surfaced aluminum foil is glued to the prepared substrate by reflow of the coating layer on the bottom side by overlapping welding of the loosely lying material. The welding is performed by gas or other burners.

Preparation of the substrate for laying the self-adhesive foil

The basis for placing the adhesive foil material must be processed with bitumen primer. The primer is applied over the entire surface, including vertical.

To avoid moisture and contamination of the primed surface with dust, laying of the material must be carried out immediately after the primed surface dries.

Laying of the material

Self-adhesive aluminum waterproofing foil is placed in a single layer. Laying of the material must be started from the lowered areas up the slope. Before laying the material is rolled out and tried on at the place in order to achieve a snug fit of the sheet to vertical and other adjacent surfaces.

When fitting a roll of the next row, the overlap is exposed to 4-5 inches in the longitudinal direction. Next, the sheet is gently rolled up to the middle from the side of its initial gluing. With the help of a roofing knife anti-adhesive film is cut in the middle of the roll from the gluing side.

For better gluing of the sheet in the corners and at the junction to the vertical walls, the material is rolled with a silicone roller.

For better gluing of the sheet in the corners and at the junction to the vertical walls, the material is rolled with a silicone roller.

In the area of the side overlap the protective release sheet is removed from the seam and the edge is smoothed with a brush. Side laps are further rolled with a manual roller.

To ensure the tightness of the end overlaps their value should be at least 6 inches. The area of the end overlaps is covered with a layer of bitumen-polymer gluing mastic. The splice of the sheets is rolled with a silicone roller. Mastic is to squeeze out of the lap while stitching.

After completion of gluing material closures and formation of internal and external corners, proceed to the final stage of the roof mounting. The upper edge of the material is attached to a metal rail fixed with screws. The distance between the rails should be 5 – 10 mm.

Aluminum waterproofing membrane for protection and insulation