Several common methods describing how to build a basement wall. Some useful tips on mounting waterproof system and insulation of basement walls.

The issue of covering the walls in the basement is, of course, very important, but first you need to have full information on how to build a basement wall.

Technological nuances of developing basement walls

Comfortable operation of the basement and the house in general depends on how correctly the foundation system has been developed. Basement walls bear the load of the building weight; therefore their strength reserve shouldn’t be questionable.

Talking about the basement under the building, the concepts of “basement walls” and “foundation” are inseparable. Many people believe that the concrete strip, which supports the walls of the basement, is a foundation as such.

Installation of monolithic concrete walls in the basement

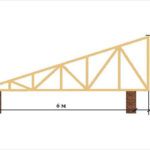

If the basement is deepened completely, the best solution can be a monolithic strip construction. There are several ways to build a monolithic basement your own hands. The most common option is the use of removable formwork. It is assembled of cut boards, ready-made boards or large blocks.

If the basement is deepened completely, the best solution can be a monolithic strip construction. There are several ways to build a monolithic basement your own hands. The most common option is the use of removable formwork. It is assembled of cut boards, ready-made boards or large blocks.

But there is a more convenient method: you can use concrete blocks with through cavities as a permanent formwork. They are placed on each other so that the voids form through channels. Subsequently, they are mounted with vertical fittings and pumped with concrete.

To begin the construction of basement walls, you must wait till the concrete foundation strip and the subfloor get solid enough. If the walls are built of brick, the support (wider) part of the wall is laid first.

How to build a wall in a basement of brick

When brick is used for the construction of a cellar, all the calculation results increase as it is inferior to characteristics of concrete blocks in strength.

Usually, professional masons begin all bricklaying from the corners, and then hold it up to the 7-8th row. Then the bricklaying continues between the corners. For the tougher masonry every few rows are packed horizontally in a grid of fitting. But here the layer of solution must be increased at least in half the inch so that the entire fitting frame is hidden in the solution.

How to build a basement wall using concrete blocks

Wall development by using the blocks is perhaps the most convenient system of construction of basement walls. For such type of design, at the depth of 7 ft and the span length of 10 ft, the wall thickness must be 10 inches, and the width of the base plate must be 16 inches. In case you make the foundation 2 ft deeper, the width of the strip grows up to 20 inches. That is, only foundation blanket gets wider in this case; wall thickness remains constant. If the wall length increases (over 10 ft), its thickness is expected to increase as well.

Wall development by using the blocks is perhaps the most convenient system of construction of basement walls. For such type of design, at the depth of 7 ft and the span length of 10 ft, the wall thickness must be 10 inches, and the width of the base plate must be 16 inches. In case you make the foundation 2 ft deeper, the width of the strip grows up to 20 inches. That is, only foundation blanket gets wider in this case; wall thickness remains constant. If the wall length increases (over 10 ft), its thickness is expected to increase as well.

As in the masonry, blocks are stacked from angles. For reliable bonding between the blocks a special adhesive solution is applied usually.

Prefabricated foundations aren’t inferior to monolithic structures in strength as factory reinforcing is performed with a huge margin of safety. Only foundation blanket is supplied with fittings while foundation blocks aren’t. Their strength is enough for construction of an ordinary one storey house.

Basement waterproofing

First, basement walls are covered with a layer of primer, which will increase the level of adhesion. Then, the surface is coated with bitumen or roofing felt. This will be the pressure waterproofing that can withstand direct contact with water. Also for these purposes you can use special mastic. After that the pit walls are shrouded with plastic wrap. It will serve as an additional protection for the drainage system.

First, basement walls are covered with a layer of primer, which will increase the level of adhesion. Then, the surface is coated with bitumen or roofing felt. This will be the pressure waterproofing that can withstand direct contact with water. Also for these purposes you can use special mastic. After that the pit walls are shrouded with plastic wrap. It will serve as an additional protection for the drainage system.

The next step is to backfill free space of the pit with 4-8 in of gravel and place coarse sand that is being watered for better sealing. At the final stage the concrete paving is mounted for protection against moisture coming from the surface.

How to insulate a basement inside and outside

The outer insulation of the basement is performed using 2 inch thick foam. Sheets of this material practically do not require mounting. They are stuck pointwise with special foam, and further work is made by the soil that fills the space around the ground floor.

The outer insulation of the basement is performed using 2 inch thick foam. Sheets of this material practically do not require mounting. They are stuck pointwise with special foam, and further work is made by the soil that fills the space around the ground floor.

Internal insulation is carried out using mineral wool and plasterboard. In this case, the external walls of the basement are paneled with plasterboard, and the space between plasterboard and concrete is filled with mineral wool. In order to save space, you can recourse to the so-called insulating plaster. Its efficiency is much lower, but in combination with external insulation the effect will be quite sufficient.

Special attention should be paid to the fact that while planning how to build a basement wall the calculations are held exclusively individually. This requires information on the type of soil, the level of groundwater and climate characteristics of the particular area.