Types of bitumen waterproofing materials. Pros and cons for application of bitumen based coating. Tips on using hot and cold bitumen mastic.

To extend life of monolithic structures and protect them against ingress of moisture and, consequently, to reduce the probability of occurrence of dampness and mold inside the house it is required using waterproofing material. Bitumen waterproofing is the most common, easy and inexpensive way. Bitumen itself is waterproof and, most important, it is completely impervious to the destructive impact of moisture.

To extend life of monolithic structures and protect them against ingress of moisture and, consequently, to reduce the probability of occurrence of dampness and mold inside the house it is required using waterproofing material. Bitumen waterproofing is the most common, easy and inexpensive way. Bitumen itself is waterproof and, most important, it is completely impervious to the destructive impact of moisture.

Not only the low cost of the materials is of great importance, but also the ease of use: e.g. for bitumen based waterproofing of the foundation no special equipment or professional skills are required. This greatly reduces labor and related costs.

Advantages and disadvantages of bitumen waterproofing

Major advantages of waterproofing with bitumen mixture are:

- inexpensive material;

- ease of performance;

- high resistance to mechanical damage;

- the ability to cover complex surfaces.

Main drawbacks of bitumen coating consist of its ugly appearance and the fact that it “flows” on the sun, as well as difficulty of applying to other materials, such as plaster or paint. However, the above-ground part of the foundation can be covered with polystyrene foam for insulation (preferably with a recess of 24-28 inches), and now it is easy to putty or plaster.

Main drawbacks of bitumen coating consist of its ugly appearance and the fact that it “flows” on the sun, as well as difficulty of applying to other materials, such as plaster or paint. However, the above-ground part of the foundation can be covered with polystyrene foam for insulation (preferably with a recess of 24-28 inches), and now it is easy to putty or plaster.

Considering the fact that the method described herein is easy to use even without the basic knowledge and skills, it remains quite a reliable and proven way of waterproofing, which has been used for a hundred years and continues being applied till now.

What materials are supposed to be applied?

- Bitumen rubber mastic. The mastic comprises bitumen and organic solvents; it does not require heating and is ready for use. It is applied to the surface in multiple layers. You can use it to protect pipelines and other technical designs against

- The primer is a fine mixture of bitumen and rubber; it is made on water base, which makes it easier to work with indoors. As the light capillary waterproofing it can be applied independently.

It is used in waterproofing mainly as the gluing agent coating the surface before laying one sheet to another. It is suitable for bonding bituminous building roofs with each other, and for their attachment to any other surface. Bitumen primer penetrates deeply, dries quickly and provides a secure fixation of waterproofing materials.

It is used in waterproofing mainly as the gluing agent coating the surface before laying one sheet to another. It is suitable for bonding bituminous building roofs with each other, and for their attachment to any other surface. Bitumen primer penetrates deeply, dries quickly and provides a secure fixation of waterproofing materials.

- Bitumen latex waterproofing emulsion is a fine compound of two mutually insoluble liquids (bitumen and water), whereas bitumen is dispersed in water in the form of particles with a diameter of 540 microns. The latex in the emulsion acts as a filler which increases the strength and elastic properties of the material.

The emulsion is applied by the mechanized way with the help of airless spraying machine. Waterproofing made of bitumen latex emulsion is durable (over 45 years) due to the homogeneous structure and stability of the emulsion properties, good compliance of latex and bitumen and resistance to influence of aggressive liquids (solutions of sulfuric and nitric acid, sodium sulfate, chlorinated lime etc.)

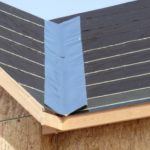

- Bitumen sheet waterproofing is used for the roof covering and for the protection of the foundation. The material is characterized by non decaying base of polyester, glass fabric and glass fiber. The material on both sides is impregnated with bitumen, which is mixed with a plasticizer. Due to this combination of materials, it is elastic and resistant to cracking.

Waterproofing rolls are mounted with the help of gas burners.

How to apply primer and putty

The primer should be applied to the clean wall with a brush or roller. After drying it can be applied once more, if a significant portion has been soaked into the surface of the wall.

Bitumen mastic is applied with a brush or a trowel. After drying of the first layer (about a day) it is better to put one more to increase the quality of insulation.

Application of bitumen waterproofing putty

For the application of hot bitumen mastic the latter should be heated to 274F, so that it is easy to apply and penetrates well into all the cracks and irregularities. Heating is not required for cold mastics, they are immediately ready for use, but they are more expensive than the first option. Cold mastics require heating at ambient temperature of 41F. They are made from furylic, epoxy and other resins on synthetic base.

For the application of hot bitumen mastic the latter should be heated to 274F, so that it is easy to apply and penetrates well into all the cracks and irregularities. Heating is not required for cold mastics, they are immediately ready for use, but they are more expensive than the first option. Cold mastics require heating at ambient temperature of 41F. They are made from furylic, epoxy and other resins on synthetic base.

Before carrying out waterproofing with bitumen mastic the surface should be treated with the composition of bitumen and solvent. Then the compound is applied by brush, roller or a faster way – by using a sprayer or paint gun. Flame-spraying method presupposes application of at least two layers with a time interval of about 15 hours. The thickness of the bitumen thus should be 2 mm.