Types of materials used for making a liquid waterproofing membrane. Ease of processing the surface with liquid waterproofing. Application of liquid rubber.

Application of the waterproofing coating, which would not have seams, could be easily attached to the structure with corners or curved surfaces, and thus last long, has been just a dream until recently. Today, such a technology of coating is called liquid waterproofing membrane. At the stage of practical application, it is a liquid substance. After coating the surface the polymerization process occurs and liquid state of the material changes into solid or semi-soft state.

Types of liquid waterproofing materials

Liquid glass is a water solution of potassium and sodium salts. It is the most affordable option for liquid waterproofing. It can be applied to the concrete base using conventional spray or brush. Pre-priming is not required, because the material is so fluid that it fills the microcracks and small pores.

Liquid glass is a water solution of potassium and sodium salts. It is the most affordable option for liquid waterproofing. It can be applied to the concrete base using conventional spray or brush. Pre-priming is not required, because the material is so fluid that it fills the microcracks and small pores.

Liquid glass is used for processing of interior and exterior parts of the walls and concrete floors. The material has no odor and color. The treated surface is guaranteed to be protected from moisture and corrosion within 4-5 years.

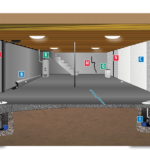

Liquid silicone membranes are used for waterproofing treatment of roofs, balconies, floors and walls of bathrooms and wet areas; for internal waterproofing of basements; waterproofing under ceramic flooring and wall tiling. It also suits for repair of flat roofs without removing the old bitumen coating and for repair of leaks occurring at the intersection of dissimilar materials.

The main feature of these materials is that they have all the advantages of silicone coatings and sealants, but have a high adhesion to any materials including wet, have high elasticity and vapor permeability and can fill in large cracks. They can be applied on vertical and horizontal surfaces.

Silicon liquid membrane is non-toxic, non-combustible and odorless and can be applied not only outside, but also indoors. The silicon membrane is polymerized at ambient temperature owing to atmospheric moisture. The membrane can be applied by a spray gun.

Also read: Waterproofing materials for construction

Polyurethane liquid waterproofing membrane

Liquid polyurethane material forms an elastic waterproof membrane. It is applied and polymerized in any conditions, including subzero temperature. Liquid polyurethane membrane polymerizes under the influence of atmospheric moisture. It has got following benefits:

Liquid polyurethane material forms an elastic waterproof membrane. It is applied and polymerized in any conditions, including subzero temperature. Liquid polyurethane membrane polymerizes under the influence of atmospheric moisture. It has got following benefits:

- easy to use (applied with a roller or airless spray),

- forms a seamless membrane,

- waterproof,

- frost resistant,

- provides vapor permeability,

- full adhesion to the substrate without fixing,

- in case of membrane damage, it is possible to remove defects rapidly,

- low consumption.

Polyurethane liquid applied waterproofing membrane is used for protection of roofs, balconies and terraces, bathrooms, swimming pools, waterproofing of concrete structures such as bridges, tunnels, for the protection of foam insulating materials. It can be applied to existing concrete, roofing geotextiles, brickwork, asbestos cement slabs (depending on the state of the surface you may need to apply the primer first).

The material is applied to the cleaned surface with the roller under normal conditions. You can use airless spray, greatly reducing labor costs. Problem areas such as joints between the floor and walls, chimneys, pipes, etc. are reinforced with geotextiles. Such factors as porosity, temperature, humidity, application method and final requirements can affect the consumption.

Application of liquid rubber

Liquid rubber is a two-component waterproofing and roofing material based on an aqueous polymer modified bitumen emulsion with special polymeric and elastomeric additives.

Liquid rubber is a two-component waterproofing and roofing material based on an aqueous polymer modified bitumen emulsion with special polymeric and elastomeric additives.

Application of the sprayed membrane coating of liquid rubber is versatile; it is a perfect option when there is a need of a gas-tight membrane, waterproofing and protection against corrosion. Liquid rubber binds with same material (a new layer on top of the old one) at the molecular level creating the effect of “welding”, regardless of the age or stage of hardening of the previous coating.

Sprayed liquid rubber has a number of indisputable competitive advantages:

- the ability to process complex surfaces;

- high maintainability;

solid adhesion to most construction materials (brick, wood, concrete, metal and so on);

solid adhesion to most construction materials (brick, wood, concrete, metal and so on);- seamless film that protects the surface from destructive effects of water, corrosion and chemicals;

- no joints, overlaps;

- resistance to temperature changes;

- minimum requirements for the preparation of the treated surface;

Manufacturers supply liquid waterproofing membrane in liquid form and in the process of sputtering when applied to the coated surface in a short time acquires properties of thick, flexible, seamless protective coating.

Liquid waterproofing membrane, the advantages of its application