A precast concrete foundation is used as a structure basis for a variety of objects. Let’s examine in detail its features, pros and cons.

In the construction business the word “foundation” means building part taking all loads and transmitting them to the base. In this case, the base is ground. Recently a precast concrete foundation is widely used. Such constructions are placed around the whole structure perimeter, including each wall and outbuildings. It is mainly used in low-rise structures.

In the construction business the word “foundation” means building part taking all loads and transmitting them to the base. In this case, the base is ground. Recently a precast concrete foundation is widely used. Such constructions are placed around the whole structure perimeter, including each wall and outbuildings. It is mainly used in low-rise structures.

Special blocks and foundation cushion under them are made for this purpose. These blocks are both full-bodied and hollow. The first is made of rubble concrete. The second one is made in production, mainly of conventional concrete, but sometimes – silicate. Reinforced concrete is also a common material for the production of blocks.

Pros and cons of precast concrete foundations

- Quick assembly design. Just a couple of hours after the end of installation work you may begin the wall construction. It is not needed to wait for a month or more, as in the case of using a monolithic base;

- A significant cost reduction of building materials. If you choose to place bar details not continuously side by side, but at a short distance from each other, you may reduce to 25% of materials.

Disadvantages list:

- Such a basement can not be enhanced by installing additional reinforcement cage, the blocks production is standardized;

- The rigidity of assembly is less then the monolithic analog.

Precast concrete basement types

Depending on the installation depth according to the level of soil freezing this kind of basement is divided into 2 types:

Depending on the installation depth according to the level of soil freezing this kind of basement is divided into 2 types:

- Finely recessed;

- Recessed.

A recessed foundation is laid below the level of ground freezing. To set such a structure you need to dig a desired size trench, and then lay a foundation cushion. During the installation of bar details, place them tightly after brushing with a cement solution.

A finely-recessed basement is above the freezing ground. It is used in the construction of small buildings or in areas, where there is an increased level of groundwater. Installation in this case is performed in the same way as in the embodiment with a deep foundation.

Installation nuances

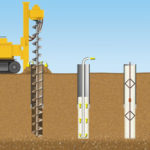

During laying concrete blocks in inconvenient joint places of interior and exterior walls you have to adjust sizes of these details for the whole basement ligation. Therefore, this process is a gradual putting of several units into the prepared trench.

When arranging the block laying you need to use an elevating crane that can also cause some discomfort. If the structured area around an object is quite large, a crane jib may not be enough for laying details of interior walls. Therefore, it is necessary to consider such details in advance.

The installation process step by step

Perform this process in the following order:

Basement cushions setting. They are installed only on a prepared sand base. But first you need to set angular elements orienting on future building axes, then tighten twine at a distance of 2 inches, which must be counted from side faces. Later, set intermediate blocks, guiding by taut twine.

Basement cushions setting. They are installed only on a prepared sand base. But first you need to set angular elements orienting on future building axes, then tighten twine at a distance of 2 inches, which must be counted from side faces. Later, set intermediate blocks, guiding by taut twine.- Reinforcement. Lay a reinforcing mesh on a surface of cushions, thus observe the distance that is measured, starting from the outer reinforcing bar and ending block edges. It must be at least 30 mm. After completion of reinforcing mesh stacking, it is filled with a cement solution layer.

- Blocks installation. When these details will be in the suspended condition, beneath them in any case should not be people. The lifting process is made by slings of special equipment.

- Making technological holes. During assembly make technological holes for sewage and water. For this purpose, arrange the units broaden so that getting cutouts could be closed up with a next row. After mounting process these formed apertures are poured with cement solution.

- Waterproofing. Precast concrete foundations require mandatory exterior waterproofing and soil backfilling, which subsequently is compacted.