To make an erecting building durable and its walls strong enough that will not need constant repair work, you should build a solid foundation. Pouring of basement construction is a complex process that requires certain stages. Let’s examine in details the complicated process how to build a concrete foundation and make it durable for many years.

Concrete basement composition

Concrete is a mixture of dense consistency, which includes cement, water, gravel and sand. It is also possible to include other important additives, which allow to give this mixture several special properties. For example, adding there surfactants or plasticizers you can increase frost resistance, water resistance and other properties.

Concrete is a mixture of dense consistency, which includes cement, water, gravel and sand. It is also possible to include other important additives, which allow to give this mixture several special properties. For example, adding there surfactants or plasticizers you can increase frost resistance, water resistance and other properties.

When choosing the composition of concrete mix you should consider the ratio of water and cement. Correct proportions can help you to build a reliable and durable basement for many years servicing. Fillers included in this mixture have really important roles. They are designed specially to reduce internal stresses and shrinkage of structure. Fillers (sand and gravel) influence on strength of the finished material and its total cost. Recommended average proportions should be: 1:3:3 cement/gravel/sand.

It is important to mix the mixture well that will achieve desired characteristics of the finished solution. The periodic concrete mixing during the delivery and preservation of the original water-cement ratio can help to achieve facts that your solution will maintain a certain viscosity and not begin to solidify.

Required tools

Concrete basement construction with your hands may require following tools:

Concrete basement construction with your hands may require following tools:

- water level for accurate alignment of the formwork and foundation pouring;

- bayonet or scoop spades, trowels and buckets for solution mixing;

- roulette to measure all assembled parts of the formwork;

- cruciate screwdriver and screws, or hammer and nails for assemblage of wooden formwork;

- large flat sheet or concrete mixer to prepare a solution.

Pouring options

There are several options of basement filling up:

- Order a ready solution that may be brought directly to the construction area. In this case, the pouring process can be made with your own hands for one time and cold welds will not appear on the basement. Exactly in these areas, first of all, cracks are formed, which reduces the strength of the whole base. But this process is quite expensive because of preparation and delivery payments. Many homeowners do not consider it as a perfect way because they prefer to save extra money.

- Perform the pouring process with your hands. In this case, you need some help of a few strong friends and a week of free time;

- Take advantage of ready-made concrete blocks and fill up their junction with a solution. In some way this process accelerates the construction building, but also leads to the significant cost increasing.

Pouring process details

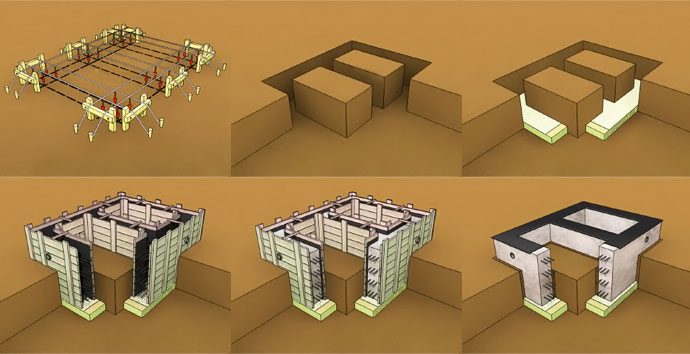

You may pour the readymade solution in several ways:

- in readymade trenches, where sides will be formed by the ground;

- in prefabricated wooden formwork.

Pouring of prepared mixture can be carried out without a frame, if walls here may serve as a solid ground and water of concrete will not go away quickly, but if the soil is friable and soft, then it will be necessary to collect formwork frame.

In the second case, your mixture will not quickly lose moisture and dry out gradually, acquiring required hardness and strength. The formwork is assembled of wooden boards or moisture-resistant sheet material.

The mixing process also has its secrets and features. At first, mix sand and cement in a container, stirred it until homogenous consistency. Add there some rubble or gravel, and thoroughly stirred and only then add some water. When adding water you should take into account ambient temperature. If concreting takes place in a warm period – water can be cold, or taken from a well, if works are carried out in winter or cold weather – it is better to take heated water, so your mixture will become more flexible and easier to resist for mixing.

Filling up your finished mixture should be made in small quantities and compacted carefully. Compaction can be performed with the using of:

- A compaction machine, it can be rented for a building period. This procedure can save your working time and to fully pay back your rent by fast filling up trenches for a foundation.

- A hammer, tapping on the formwork wall.

Compaction can be terminated after a concrete surface will give some water.

To save the consumption of ready solution you may use rubble – large building stones of firm breeds. But when laying pay attention to this advice: rubble should be laid on fresh concrete and immediately pour the next layer on its top. Covering with rubble of a foundation does not exclude compaction.