Information on floating laminate flooring, its advantages and the peculiarities of the installation process.

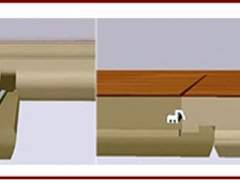

What is floating flooring? There are several systems dealing this definition. It is usually associated with a wide variety of building materials. But if you look closely, the main feature of all types of floating floors is no rigid fixation to the base. The construction of floating floors is a multi-layered cake of different materials intended to form a single structure. Nowadays the most popular and cheap material for this is laminate boards. So, here is some useful information on how to install floating laminate flooring.

The advantages of floating flooring

Why one should create complex designs of floating floors, if you already have a proven concrete screed? This is primarily due to the high sound isolation quality. This is facilitated by an independent floor covering position relative to the ground and walls. The opportunity to make it a good thermal insulation is equally important. This is especially important for the ground floor.

Why one should create complex designs of floating floors, if you already have a proven concrete screed? This is primarily due to the high sound isolation quality. This is facilitated by an independent floor covering position relative to the ground and walls. The opportunity to make it a good thermal insulation is equally important. This is especially important for the ground floor.

In addition to these advantages, we can highlight a few more:

- multi-layer floating floor screed provides strength and rigidity;

- cushioning effect, a positive effect on the locomotor system;

- ease of care.

Most of the residents of apartment buildings suffer from the impact of noise. It occurs when walking fast, jumping from the reshuffle heavy furniture, etc. Mid-floor concrete slab is not able to absorb it. The best option would be installation of a floating floor, which is able to improve the sound insulation of apartment for almost 50 %. It is easily washed and vacuumed.

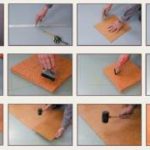

Laying floating laminate flooring

Before the installation, the material should be left for about 48 hours in the room where it will be installed – laminate boards must always adapt to the micro climate of the room.

Before the installation, the material should be left for about 48 hours in the room where it will be installed – laminate boards must always adapt to the micro climate of the room.- One of the most important conditions for a high quality floating flooring is the evenness of the base. If it has minor scratches, chips or any other small flaws – it’s not so important. But if the subfloor has significant irregularities, the lifetime of your future floating flooring will be dramatically reduced. Check the evenness using a two-meter rack. With a rail to the floor, you can see if the gap is going to form. The base should be as smooth as possible. For this purpose you must use the backing material: cellulose sheets, polystyrene, foam, etc. The insulating material used for the coating has to be very thin (3-5 mm), so almost no effect is on it (but as a gasket it is quite suitable). Installation of these materials is made on a prepared flat base with the backing layer. One of the best option is elastic foam and popular modern cellulosic materials. The thermal and acoustic insulation of these materials is provided by the fact that they are very thin, in fact. In most cases they are simply used as a substrate.

Spacing to the wall of about 0,5 inch is required due to the extensibility of the material at high temperatures.

Spacing to the wall of about 0,5 inch is required due to the extensibility of the material at high temperatures.- Not even the simple smoothness is very important for the floating flooring, but also the horizontality. That’s why it should be constantly monitored with the most common construction tools (levels).

- For the laying itself, the laminated boards are loosely placed on the floor – you start bonding them together, not forgetting the indent (0,5 inch) from the walls. This expansion gap must be left in order to prevent blistering the coating due to temperature fluctuations.

- Monitor the accuracy of the geometry using the rule of 5 or more feet long. You can replace it with a flat rack. The rule is applied to the bottom and looked up to the light. Otherwise, the irregularities of the coatings will easily damage the whole structure, and you will not be able to fix it without replacing of the whole flooring.

Tips from the pros

Floating floors are desirable to be installed at room temperature and under dry conditions;

Floating floors are desirable to be installed at room temperature and under dry conditions;- It is impossible to further cement screws, nails or glue;

- Laying is made strictly perpendicular to the windows;

- After the installation, it is necessary to leave the flooring without any contact with human feet for 6 hours and only then you may install the plinth.

There are also other types of floating floorings. Here we have talked about the easiest and adapted type of it – prefabricated floating flooring (the laminate-based one).